The 'Ins and Outs' of Commission work

The thing that takes the longest in this whole process is the initial discussions between myself and the customer as to what kind of glass panel is to be commissioned. Sometimes people have very strong ideas about what they want and others need me to provide images and ideas as a starting point. I will often visit the customers house to see where the panel will go and then from there I start providing drawings of ideas. Once the design has been finalized I then draw it out to size and order the glass. It is at this point I ask for a deposit which usually covers the cost of the glass.

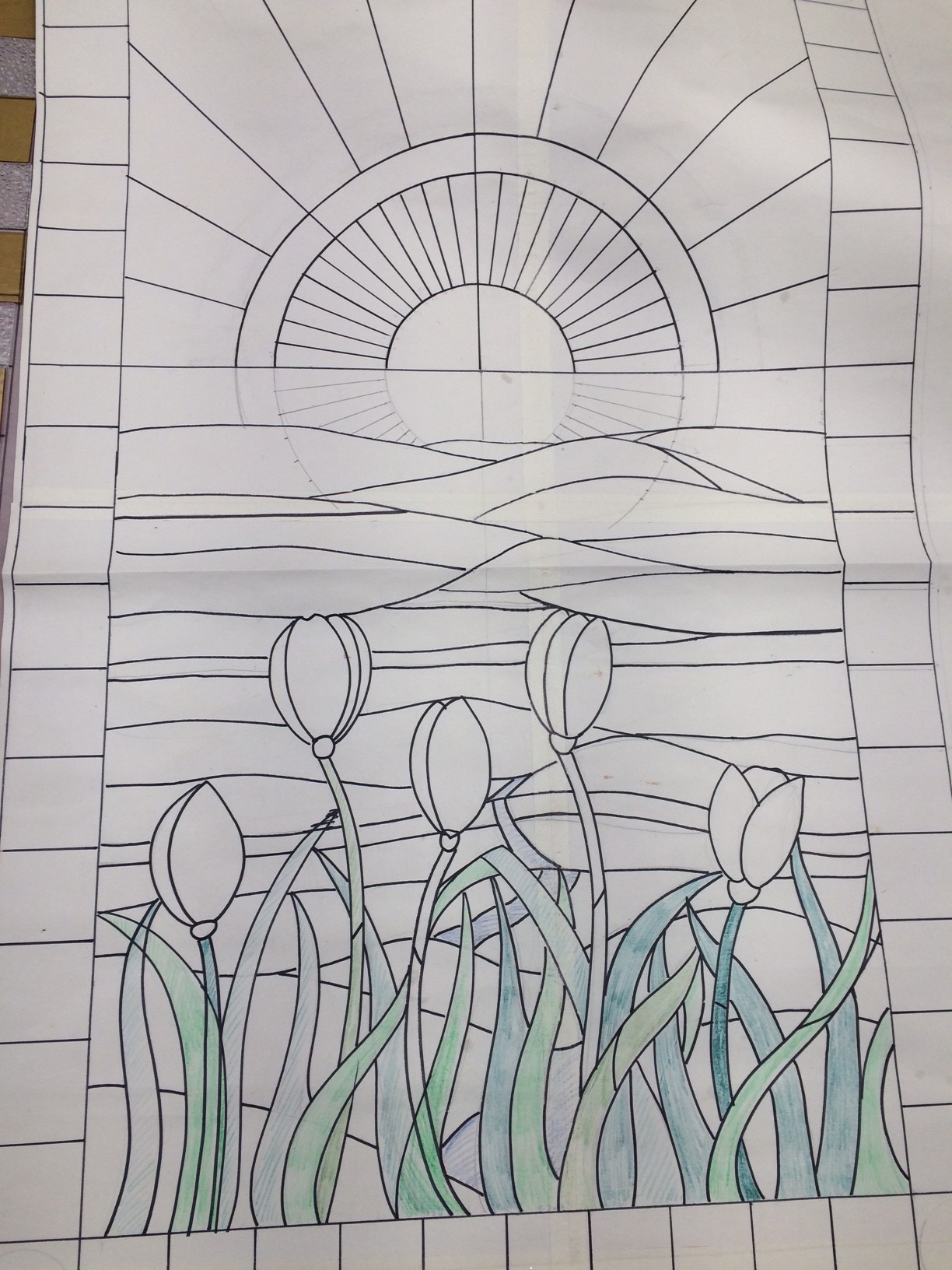

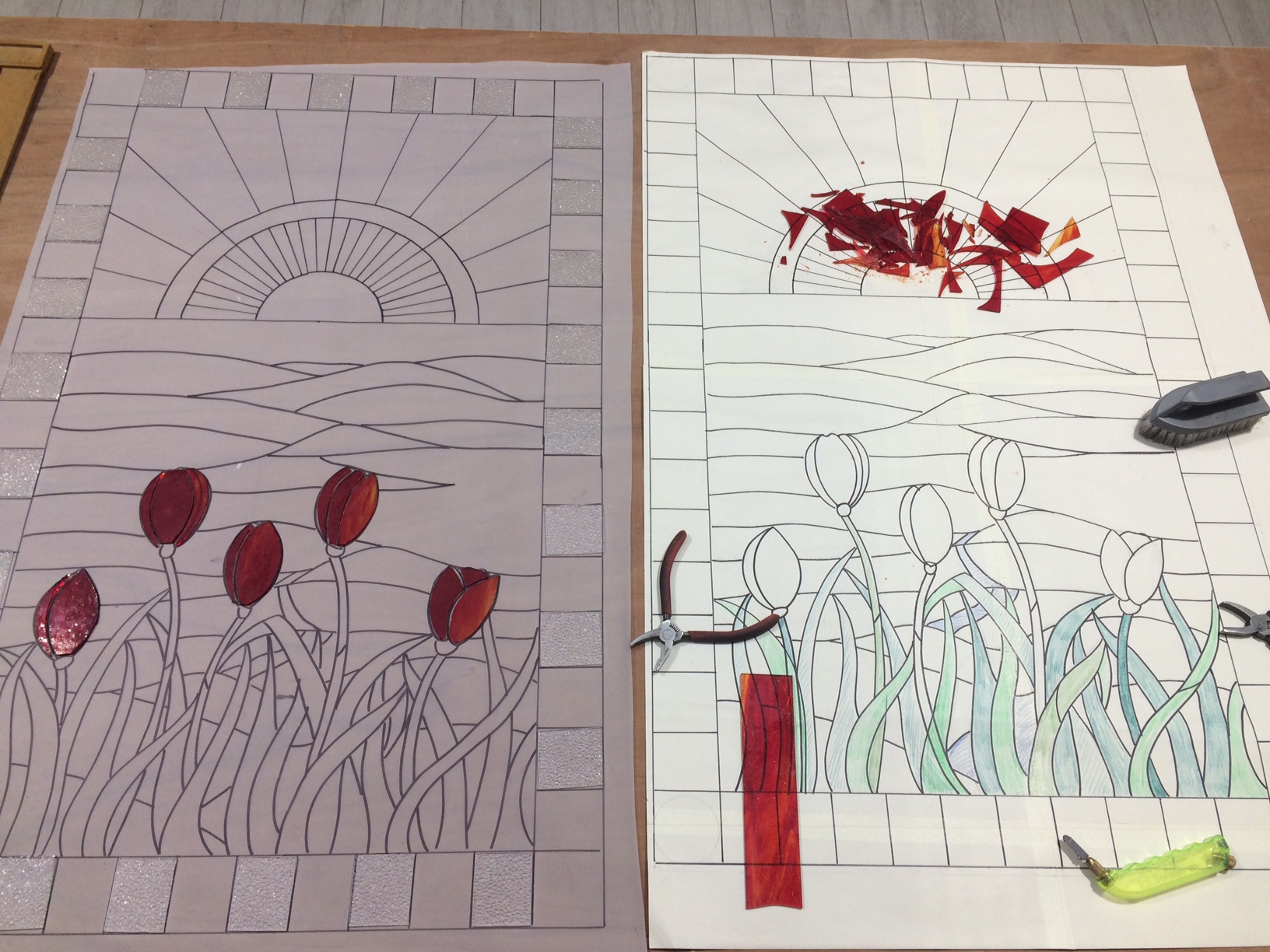

Two drawings are made, one to cut from and one to lay the cut pieces out on.

The image below shows the start of the cutting process where the tulips are being cut from the red glass.

Below you can see more of the glass cut out.

This next image shows the lead came being fitted around each piece of glass. Reinforced lead came was used in some of this piece to give added strength and because it was a large window measuring just over a meter high by 67cm wide.

The leading is the completed. Horseshoe nails keep everything in place.

Once the leading has been done each joint is then soldered so then the whole panel stays together. The last part of this process is the cementing. Cement is pushed with an old toothbrush under the lead to waterproof the piece and it is then polished.

The very last step is the installation. Both Joe,(my husband) and myself are willing to install the panel as we did with this one but we are also quite happy for the customer to install the piece.